Samsung Biologics, a leading biopharmaceutical contract manufacturing organization, has strengthened its partnership with Bristol Myers Squibb (BMS) by securing a new agreement for the large-scale production of drug substances for a commercial cancer antibody. This collaboration builds upon their existing relationship in antibody manufacturing and represents a significant milestone in their long-standing partnership.

Under the terms of the new deal, Samsung Biologics will provide drug substance manufacturing services at its state-of-the-art Plant 4 facility located in Songdo, South Korea. The contract is valued at approximately 321.26 billion Korean won, equivalent to around $242 million, according to official filings.

“Our relationship with Bristol Myers Squibb spans over a decade, and we are proud and excited to help bring important medicines to patients around the world. This collaboration with Bristol Myers Squibb underscores our commitment to expediting the delivery and ensuring the continuous supply of client pipelines, enabled by our commitment to manufacturing quality, innovation, and capacity.”

– John Rim, President and CEO of Samsung Biologics

Samsung Biologics has been actively expanding its collaborations with several pharmaceutical giants throughout the year, including a biosimilar production partnership with Pfizer, valued at $411 million in June, which was described as a “long-term” arrangement. Subsequently, in July, Pfizer extended this partnership with an additional $486 million investment in biosimilar manufacturing at Samsung Biologics’ Plant 4 in Incheon.

In addition to Bristol Myers Squibb and Pfizer, Samsung Biologics has inked agreements with prominent pharmaceutical players such as Eli Lilly, GlaxoSmithKline (GSK), and Roche in 2023. The company is also embarking on the construction of its $1.46 billion Plant 5, marking the first of four manufacturing facilities at Samsung’s Bio Campus II.

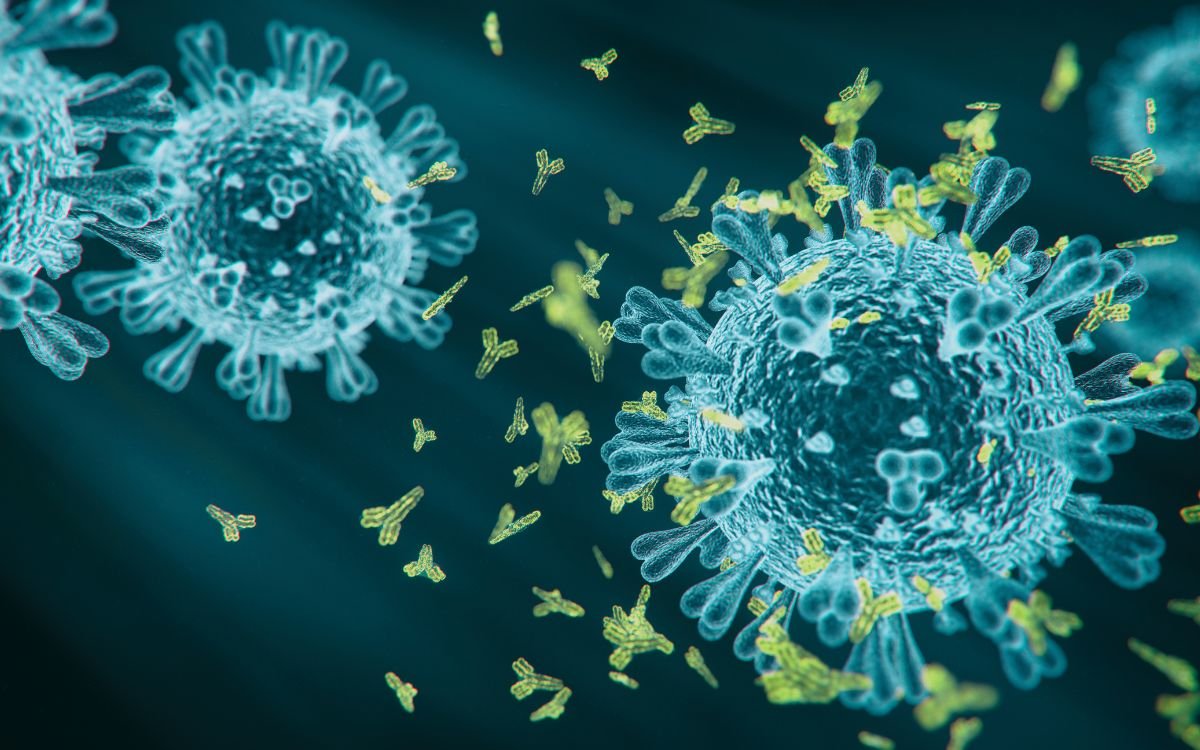

On the other hand, Bristol Myers Squibb has been actively engaged in manufacturing initiatives, including a recent partnership with Cellares, a cell therapy manufacturing specialist. This collaboration involves the utilization of Cellares’ robotic Cell Shuttle platform for automated manufacturing of CAR-T cell therapies. Cellares will conduct a proof-of-concept transfer process for the production of a BMS pipeline cell therapy, with BMS evaluating the automated process and comparability data.