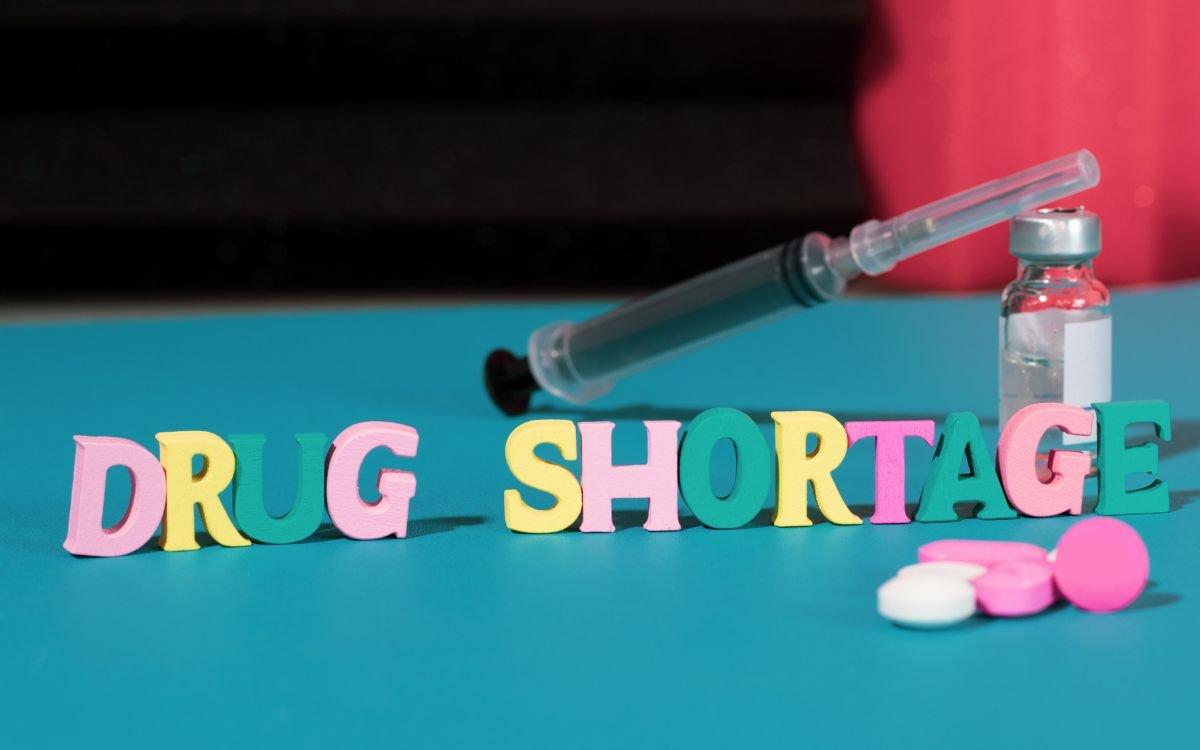

Amid concerns of potential supply shortages of critical hospital drugs, Pfizer has taken precautionary measures in response to the tornado that struck its injectables facility in Rocky Mount, North Carolina. The company has placed certain products on its emergency ordering list to ensure their availability for high medical needs.

To address the situation, Pfizer has identified 12 specific presentations of nine products, including injections for dextrose, sodium chloride, and the heart failure drug dobutamine, which can now only be ordered directly from Pfizer or its representatives until further notice. The company urges hospitals to check with wholesalers or distributors for availability and consider therapeutic alternatives before placing emergency orders.

Although the tornado mainly impacted the warehouse facility at the Rocky Mount plant, which stores raw materials, packaging supplies, and finished medicines awaiting quality assurance release, Pfizer anticipates potential long-term shortages due to the damage.

In response to the disaster, Pfizer has initiated immediate efforts to provide relief and repair the facility. Crews are working tirelessly to restore power, assess the building’s structural integrity, and relocate finished medicines to nearby storage sites.

In the final days of July, a strong tornado struck Pfizer’s Rocky Mount manufacturing facility in North Carolina. The facility’s warehouse, responsible for storing raw materials, packaging supplies, and finished medicines pending quality assurance approval, suffered significant damage, as reported by Pfizer last week.

According to Erin Fox, the senior pharmacy director at University of Utah Health, the destruction at the plant is expected to result in prolonged shortages. She shared this information with The Associated Press in late July.

The Rocky Mount manufacturing facility is crucial to the US health ecosystem, as it produces nearly 25% of Pfizer’s sterile injectables. These products, encompassing anesthesia, analgesia, therapeutics, anti-infectives, and neuromuscular blockers, account for about 8% of all sterile injectables used in American hospitals.

Pfizer’s proactive response in addressing potential shortages and ensuring the availability of critical drugs demonstrates its commitment to maintaining the supply chain integrity during this challenging time.

During the same week, Pfizer initiated immediate actions to offer aid and commence repairs at the damaged plant. The company informed that its teams were working tirelessly to restore power, evaluate the structural stability of the building, and move finished medicines to nearby locations for safekeeping.

In addition, Pfizer communicated with hospitals through a letter, identifying a specific group of products manufactured at the facility that could encounter ongoing or new supply disruptions in the near future.